Shower trays acrylate

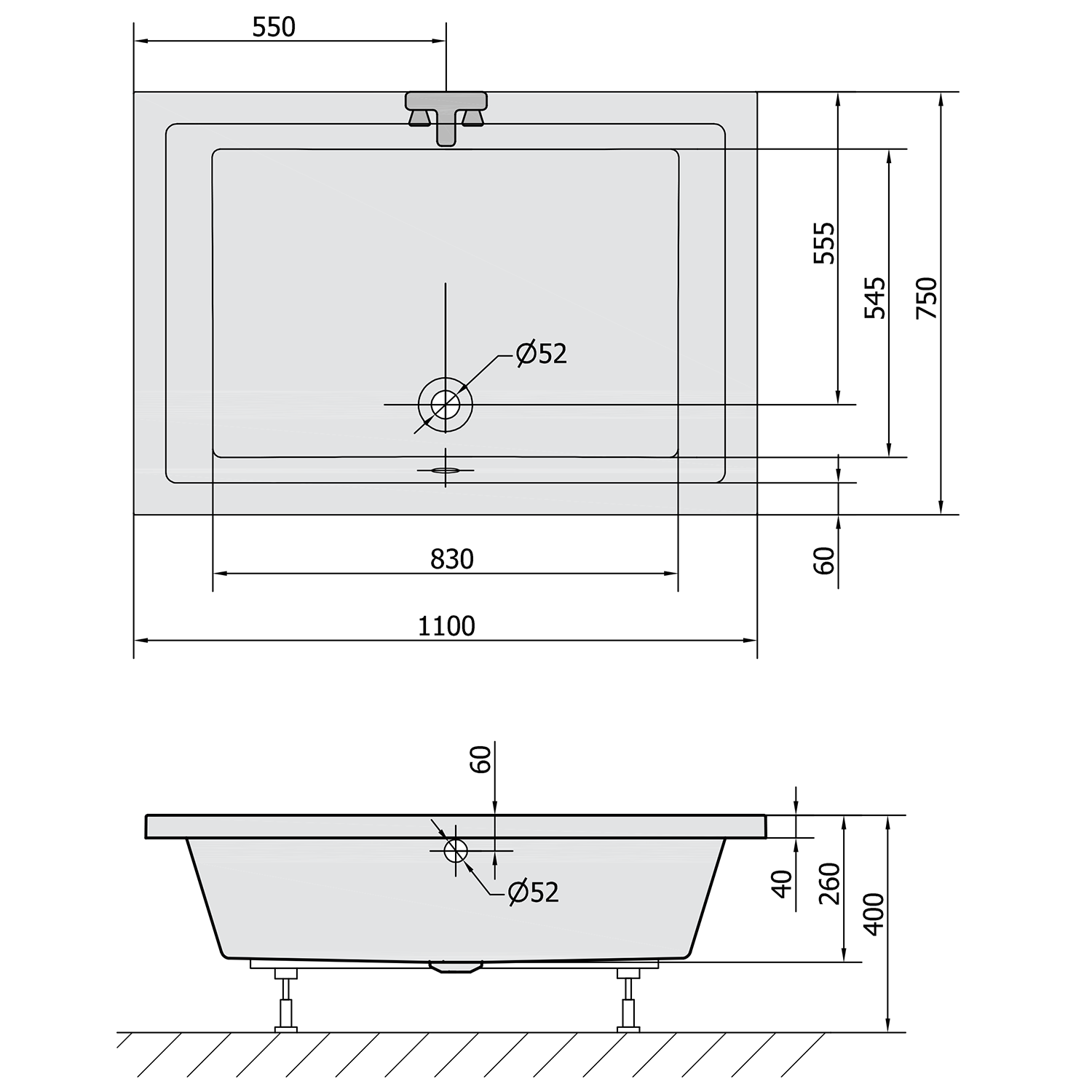

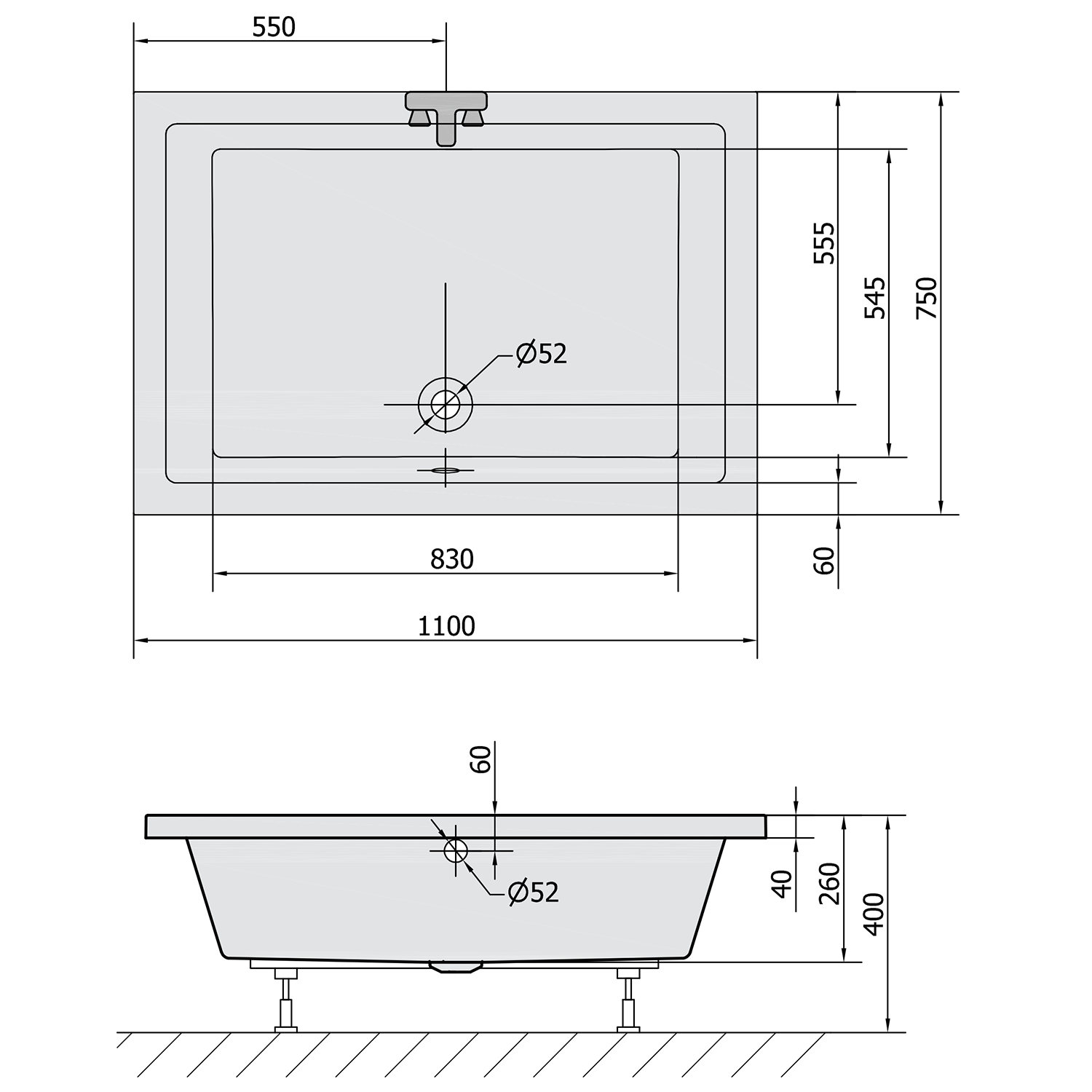

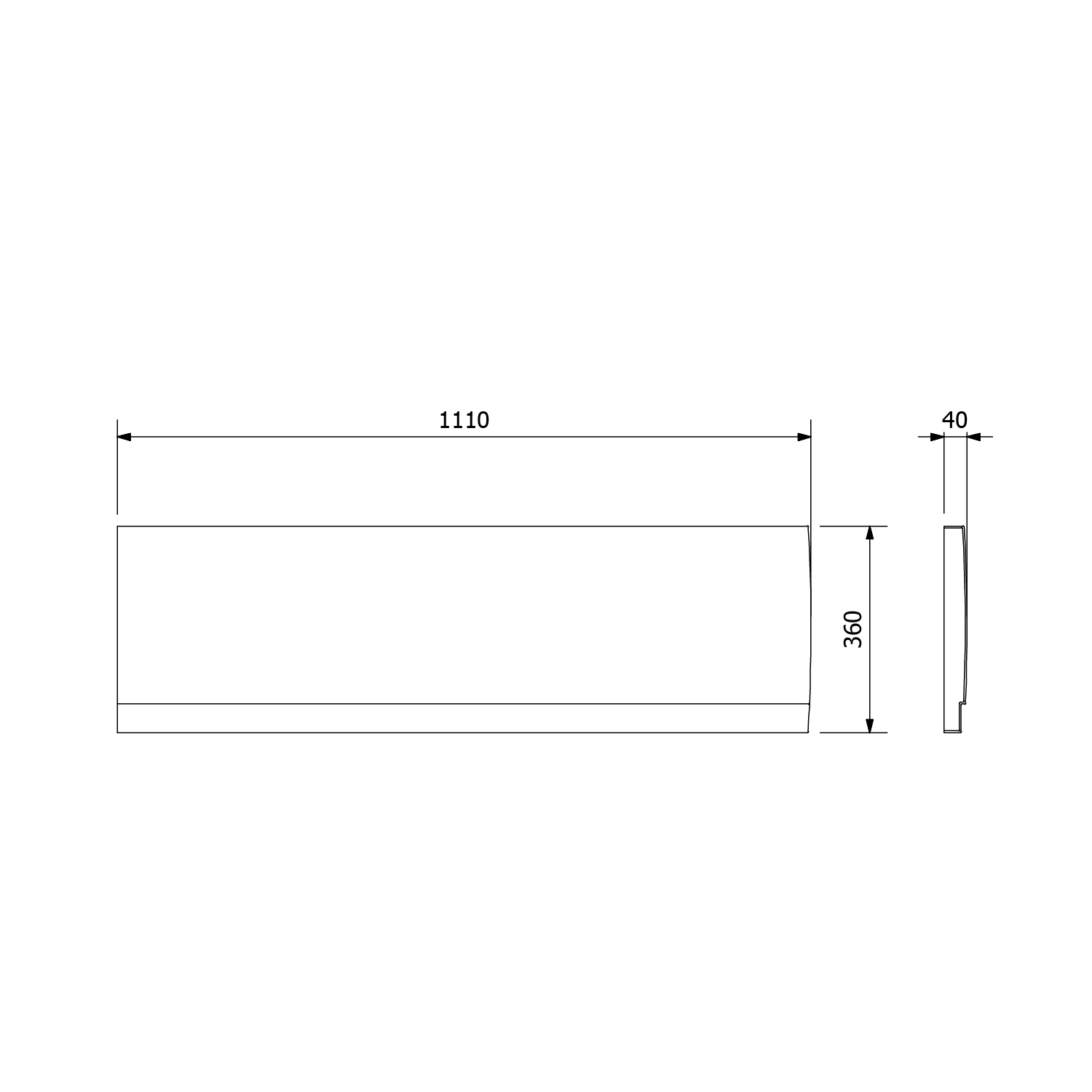

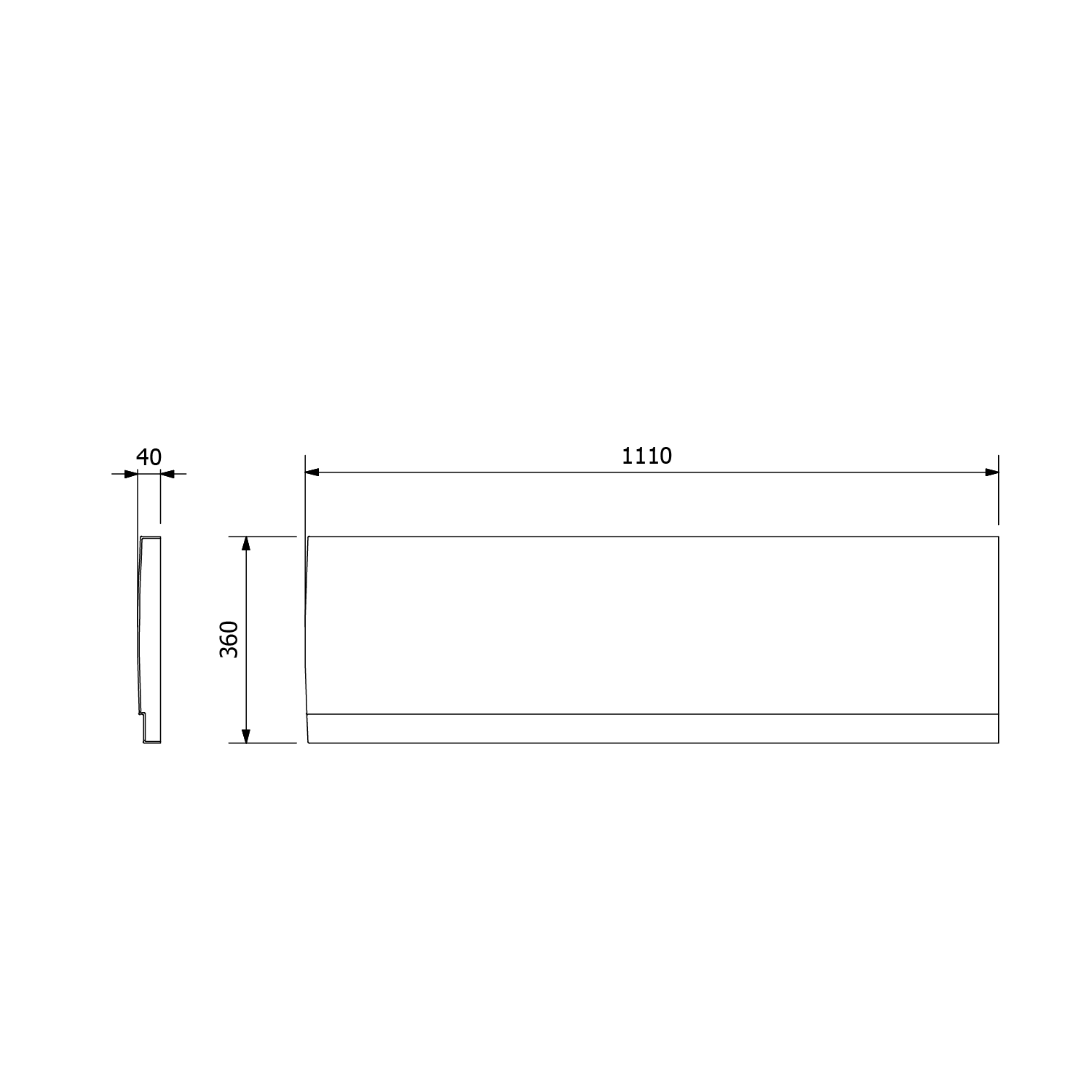

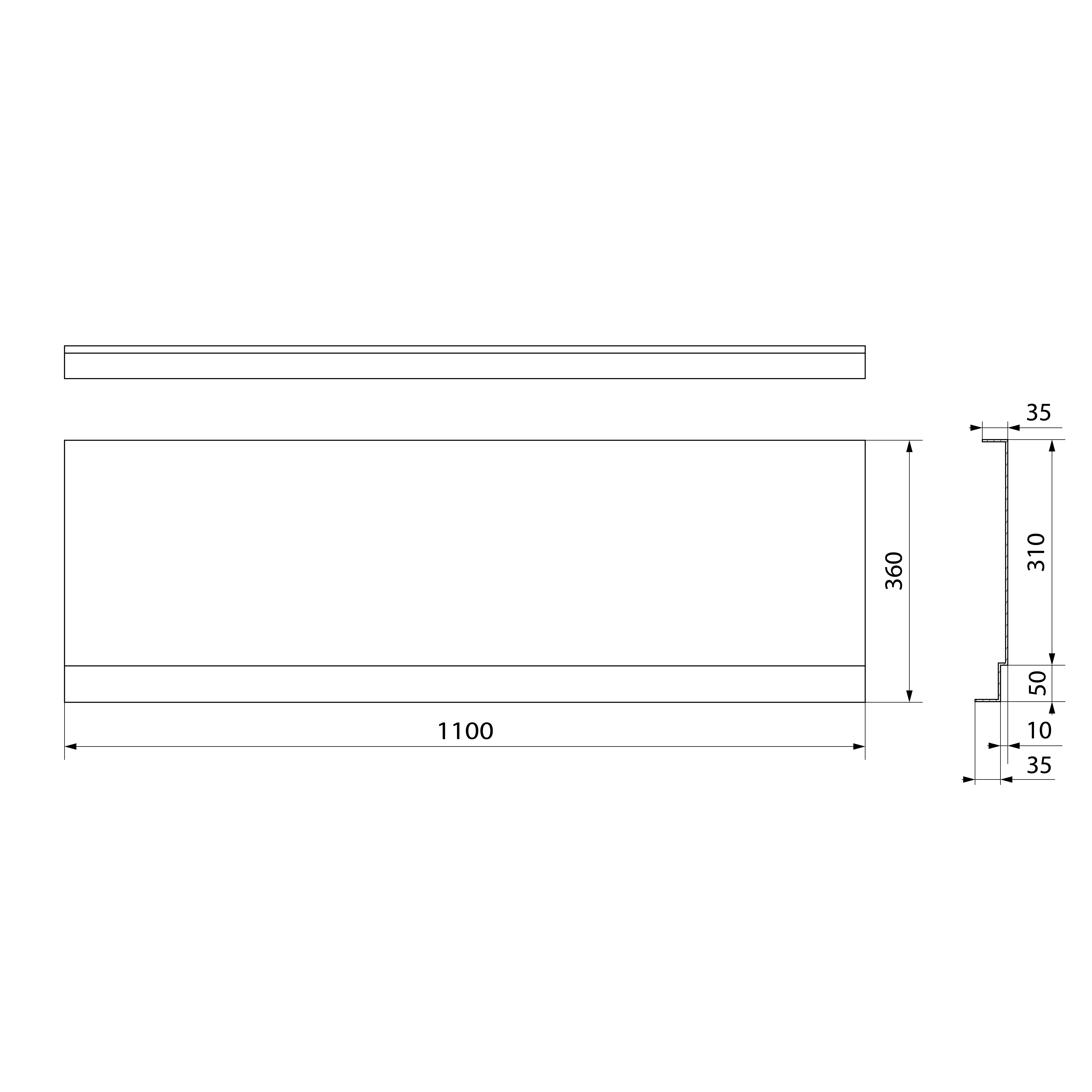

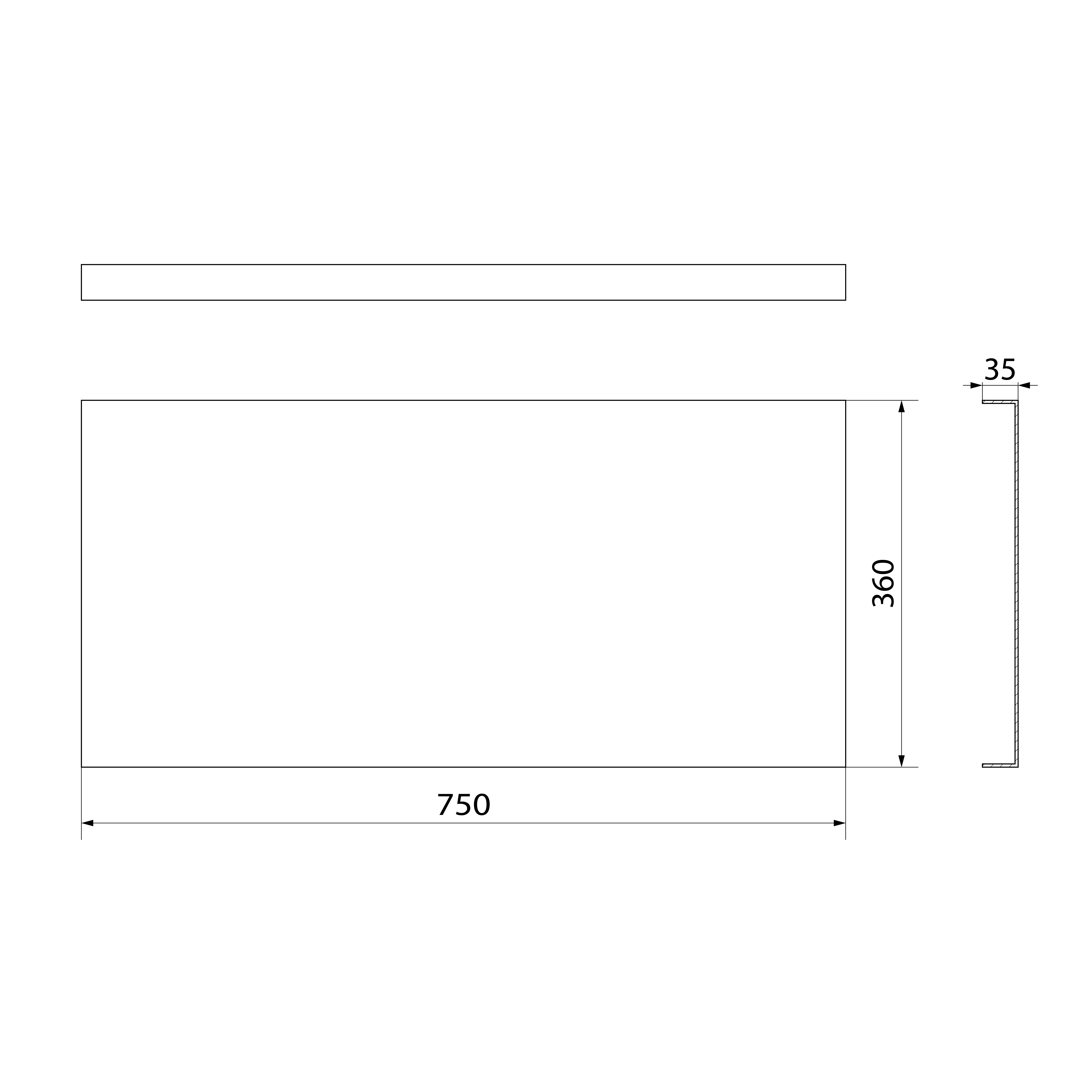

DEEP 110x75

Download

| Code | File for download |

| 72883 |

Manual 3D models 3D models 3D models 3D models Product list |

| PO60-60 |

Manual |

| FR2135 |

Manual |

| 72884 |

Product list |

| MD1116 |

Manual Maintenance Product list |

| MD3116 |

Manual Maintenance Product list |

| MD625 |

Product list |

| 83648 |

Manual Product list |

| 83659 |

Manual Product list |

| 84872 |

Manual Product list |

| 89746 |

Manual Product list |

| 71679 |

Product list |

051 white

051 white 553 pergamon

553 pergamon 651 ägäis

651 ägäis 550 bahama

550 bahama 451 whisperrosa

451 whisperrosa 951 manhattan

951 manhattan