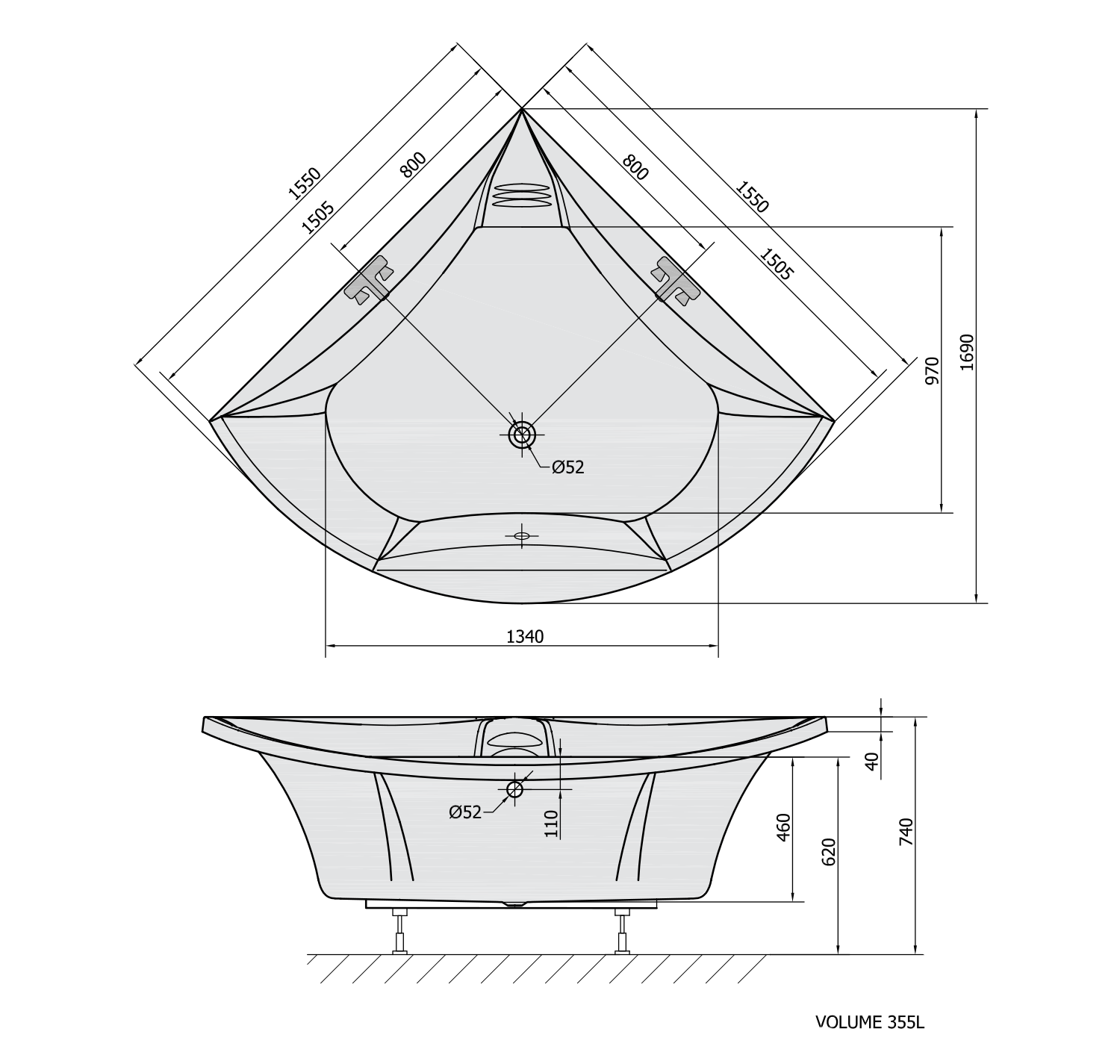

Corner baths

BERMUDA 155x155

155×155×47 cm (volume 355 l)| Code | Description |

| 33219 | BERMUDA 155x155 FRAME bath with construction |

| 33319 | BERMUDA 155x155 PANEL front |

Download

| Code | File for download |

| 33219 |

Manual 3D models 3D models 3D models Product list |

| 33319 |

Manual Product list |

Technical drawing

3D visualization

- Bermuda 155 (ACO format, size 1210 kB)

- Bermuda 155 (DXF format, size 13304 kB)

- Bermuda 155 (MAX format, size 4663 kB)

Click by right button of mouse on the link in order to download the file with 3D visualization and choose "Save as...".